ONLINE HELIUM LEAK DETECTION SERVICES

Introduction: As AEPL’s Exclusive agent KUPC LLP Introduces a state-of-the-art inspection technique to detect leaks in the negative pressure parts of Steam Condensers.Air-in-leakage is one of the worst obstacles of the Condenser’s vacuum system, which undermines the performance of the equipment

Air-in-leak results in blanketing tube surface from the steam side thereby reducing heat transfer efficiency, as air is a bad conductor of heat. Also the back pressure increase due to air in leakage causes an increase in dissolved oxygen in the condensate resulting in deposition in water wall and super heater tubes of the Boiler, turbine blades thereby leading to generation loss, extra fuel consumption etc.

Hence an early detection of leaks and arresting them would definitely improve the performance of the condenser. It is very important that the negative pressure part system of the condenser / turbine should not be neglected at any cost.

WORKING PRINCIPLE OF OUR HELIUM LEAK DETECTION TECHNIQUE

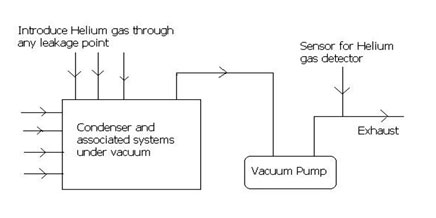

Our procedure involves spraying of a tracer gas – Helium on all the suspect areas. Helium being a lighter gas than air, gets sucked into the system due to difference in pressure in case a leaking spot is present. Helium which got sucked into the negative side of the Condenser is then sucked out through the air removal system along with the non-condensables and a sample of this ejected mixture is passed through our Mass Spectrometer to identify presence of Helium.As the Spectrometer is extremely sensitive, even minute leaks can be identified instantaneously. We will categorize the leaks as Small, Medium, Large and Very Large. This classification will help in planning the maintenance program.

Benefits

- Online Job Testing

- Increases Condenser Efficiency and hence power plant Efficiency.

- Reduces shut down times and costs

- Minimizes corrosive dissolved oxygen to get carried into the boiler system.

IDENTIFYING TUBE LEAKS IN CONDENSERS / HEAT EXCHANGERS

Our system can very effectively identify tube leaks also.The procedure adopted here is that Helium gas is sprayed into the tubes and if a leak is present, it will be carried over into the steam side of the Condenser, which is under vacuum condition and then get ejected out through the ejector / vacuum pump, where the ejected gases are tested for presence of helium using the sensitive spectrometer.

The advantage of Helium Leak Detection is that, the check for tube leaks can be done by reducing the load of the machine and isolating one half of the condenser at a time. The test can also be conducted off-line, but the vacuum on the steam side should be maintained using the vacuum pumps and also with steam dumping.

HELIUM LEAK DETECTION TESTING

We also offer service of testing of minute leaks using Helium gas for equipments like Columns, Reactors, Pipelines and Oil Platforms by positive pressure method. Typically, in these cases, we pressurize the equipment / pipeline with Nitrogen / Helium in the ratio of 90:10 to the testing pressure required by the client and check for leaks in all probable areas. Even minute leaks can be identified using our Sensitive Helium Spectrometer.

We have undertaken such jobs for two new offshore platforms top sides, a flare platform and an interconnecting Bridge for L & T Ltd. Our Engineers are well trained in carrying out the test and to interpret the results accurately. The job will be carried out by ASNT Level II Certified Engineers.

We will also conduct Helium Leak Test Services in valve component and other applications as per customer requirements

Advantages

- + Quick mobilization as per customer requirement

- + Rich Experience in the field

- + Well trained Certifeid Resources to execute the job