ACOUSTIC EYE TUBE INSPECTION

Acoustic Pulse Reflectometry (APR) is based on the measurement of one-dimensional acoustic waves propagating in tubes. Any change in the cross sectional area in the tubular system creates a reflection, which is then recorded and analyzed in order to detect defects.

In our constant urge to offer more services, encompassing latest techniques to our esteemed clients, we have added “Acoustic Eye”. This works on the principle of “Acoustic Pulse Reflectometry (APR) Technology”. Our innovative tube inspection solution is designed specifically for detecting faults commonly found in industrial tube systems: Leaks, Increases in Internal Diameter caused by Wall Loss, and Full or Partial Blockages. Building upon APR technology, Acoustic Eye has engineered a series of breakthrough algorithms that enable the system to isolate, and then identify the above faults automatically.

Benefits

Currently, the most commonly used techniques for inspecting tubes found in heat exchangers are based on invasive testing. Eddy current, Magnetic Flux Leakage, Iris Tube Inspection and Ultrasound-based methods all require a probe to be traversed throughout the entire length of each tube being examined.

Acoustic Eye, utilizes non-invasive APR technology to create a “virtual probe”, which can navigate bends, coils, elbows, fittings, etc. without difficulty. This technology lets you test any tube from a single point outside the tube in less than 10 seconds, saving considerable time and resources.

Acoustic Pulse Reflectometry

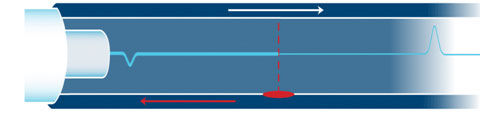

a). Probe injects an Acoustic Pulse Down the Tube

b) . Returned echoes generated by defects are recorded and analysed

c) . A set of proprietary,patented algorithms identifies and reports exact location,Type and size of inner Diameter Defects

Deployable Enviroments

- Any Tube Size up to 4″ diameter,regardless of shape or material

- Boilers,Fin Fans and Heat Exchangers

- U bends,twisted and spiral wound tubes.

- Ferrous and Non- Ferrous Metals,Graphite and Plastics.

Advantges

- Less than 10 seconds per tube.

- Fast enough for 100% inspection if/when needed

- Ideal for emergency situations

- No need for inventory of consumable Probes.