EDDY CURRENT TESTING

As AEPL’s Exclusive agent KUPC LLP is glad to offer Eddy Current Testing services, a Non Destructive Testing (NDT) that aims at detection and characterization of defects/ Flaws/discontinuities in non-ferrous tubes. Eddy Current Testing (ECT) is an electro magnetic NDT Technique widely used in Power Plants, Petro- Chemical, Refineries and other Industries for Tubular Heat Exchangers, Coolers, Condensers.

This is a surface technique and can readily detect very shallow surface defects (fatigue crack, inter-granular stress corrosion cracks etc), sub surface defects (inclusions, voids etc.) within a depth of say less than 6mm. It can also identify pitting, cracking, microbiological induced corrosion damage, support wear, erosion etc. It can easily identify material discontinuities in new tubes also. Eddy Current Testing is a simple, high speed, high sensitive, versatile and reliable NDT technique. Conventional Eddy Current Testing as per ASTM – Section – V, Article 08 & ASTM – Section V, Article 08 – Appendix 1, is used for inspection of non-ferromagnetic tubing such as stainless steel, titanium, copper, brass, cupro-nickel alloys, etc.

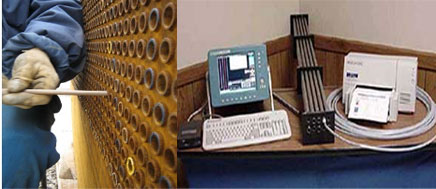

We use INSIS-EC & EX and MS-5800 advanced multi-frequency eddy current test machines. The Equipment is built with a unique parallel processor architecture centered on an embedded Pentium Processor. Extensive data-acquisition, archival, data analysis as well as reporting software is available.

We have callibration tubes for all sizes/ MoC of the tubes

ECT Inspection will be done by experienced LEVEL II Certified NDT Engineers as per ASTM standard and and service report will be given with units of low code mapping

Benefits

- Helps in Condenser Tubes Replacement Planning activity

- Assessment of residual life of the tubes

- Avoid unnecessary shutdown due to tube leakage.