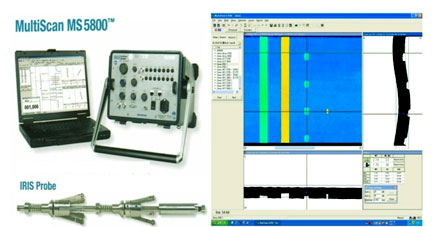

Internal Rotary Inspection System(IRIS)

Internal Rotary Inspection system(IRIS) is an ultrasonic method for the nondestructive testing of pipes and tubes.The IRIS probe is inserted into a tube that is flooded with water,and the probe is pulled out slowly as the data is displayed and recorded.The ultrasonic beam allows detection of metal loss from the inside and outside of the tube wall.

Principle of Operation

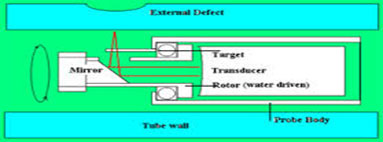

The IRIS probe consists of a rotating mirror that directs the ultrasonic beam into the tube wall.The mirror is driven by a small turbine that is rotated by the pressure of water being pumped in.As the probe is pulled the spinning motion of the mirror results in a helical scan path.One of the key settings in the proceudre is to ensure that the ultrasonic pulse initiates in the very focus point at the center of the tube or pipe.An off-center pulse will show a distorted image of the tube due to the difference in the sound path for either side of the tube wall.For that reason there are centering devices that help the operator to keep the turbine centered at all times .The transducer utilized for the inspection has to be fast(frequency) enough to bounce back at both inner wall and outer wall.For the very smallest and thinnest tubes it is usually used a 25MHZ piezoelectric transducer.IRIS is good for Fin Tubes inspection.

IRIS is an Ultrasonic pulse echo technique

The typical units inspected are

- Feed water heater

- Air fin cooler

- Condenser

- Boiler

- Heat Exchanger

- Process pipe

Advantages

- Both Ferrous and non-ferrous tubes can be inspected

- ID & OD defects can be detected

- Very Accurate & Sensitive technique .So tubes to be cleaned properly

- Three dimension picture of the defects is obtained

- The profile and its depth is provides

- Back up to ECT ,RFET and MFL inspection