Global Standard Centrifugal (GSC) Wellpoint

Global Standard Centrifugal (GSC) Wellpoint

Global Pump Standard Centrifugal Wellpoint pumps are specifically designed to effectively handle the arduous requirements of wellpoint and underdrain dewatering systems where intermittent water flow and large amounts of air are encountered. Global Pump Standard Centrifugal Wellpoint pumps provide a compact, dependable, highly efficient solution in a completely automatic priming pump with built in air separation.

Global Standard Centrifugal Wellpoint

Features

Centrifugal Wellpoint Pumps

- Rugged, heavy duty pumps engineered specifically for portable application

- Belt-driven, vacuum pump provides high air handling and a fully automatic priming system

- Fully guarded coupling, pulley and belting

- High efficiency air separation tank separates air and water before entering the pump

- Condensation chamber with drain contains any condensation or water vapor from the air

- Oil recovery system separates and removes oil and other particulates from the discharge air

- Pump casings are hydrostatically tested to 50 psig (345 kPa) above the peak casing design pressure

- Standard engine control panel provides preset emergency shutdown protection

- Standard skid-mounted format with integral fuel tank, tie downs, lifting bail and fork pockets

Options

- Fuel tanks for extended run times and/or remote location as required

- Highway trailer with integral fuel cell/chassis, lights, fenders, tie downs, lifting bail, front and rear jacks

- Trailer brakes can be offered as required

- Sound attenuated enclosure options

- Hose racks, accessory containers and other custom fabrication available as required

- Wide range of suction and discharge fittings available including Global’s own «QD» Quick

- Disconnect fittings and accessories

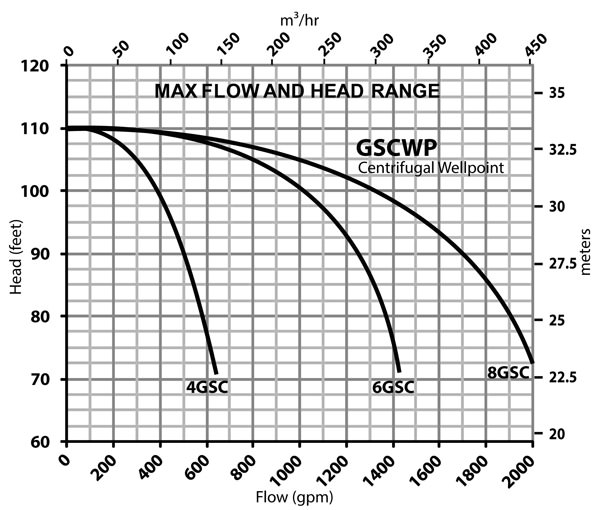

Family Curves

Sound Attenuated

Global Pump SoundGuard Enclosure

12-gauge Galvannealed-Steel (or optional stainless steel), double-sided-galvanized sheet panels insulated with a 1.25″ thick acoustical foam barrier fire retardant composite reduces noise level to no more than 68 db at 30 feet (9 m). Designed for upward exhaust of combustion gases and cooling air. Panels are removable for maintenance and repair. Panel doors, with locks, for access to the pump, engine, priming system and controls for routine servicing, lubrication and fueling.